The miso base prepared by the soybean team is salty and does not taste like miso. The miso base is fermented and aged for several months under the right temperature and humidity before it becomes miso.

"The Aging Control leader controls microorganism activity. It is an important mission to create miso of consistent quality, but when working with microorganisms, it can be a very delicate job." (Nishida)

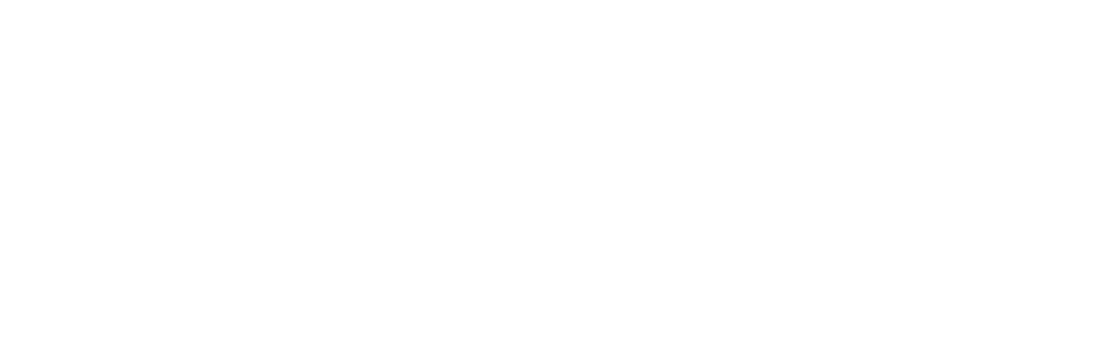

The miso base is carefully mashed so that it will ferment, and then it is stored in a large 120-ton capacity fermentation tank that extends from one floor underground to three floors above ground. A specific amount of time is spent in this large tank, and pressure in the large tank is high. If we used regular yeast, activity would decrease and the miso would not ferment properly. At Marukome, we select and cultivate our own hardy yeast that can ferment even in the high-pressure tank.

"While we are preparing the kuradashi miso used for the [Miso with Dashi Broth] in the large tanks, we are also aging "Additive-Free Miso" such as "Marunouchi Tanita Shokudo Sodium-Reduced Miso" and "Ryotei no Aji White Miso" in smaller tanks. The "Additive-Free Miso" requires active fermentation and detailed care." (Nishida)

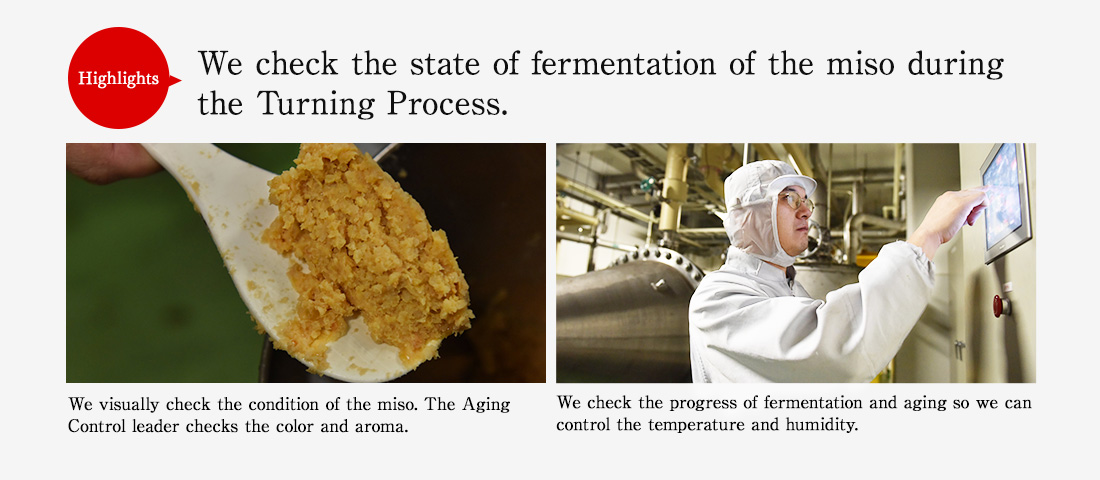

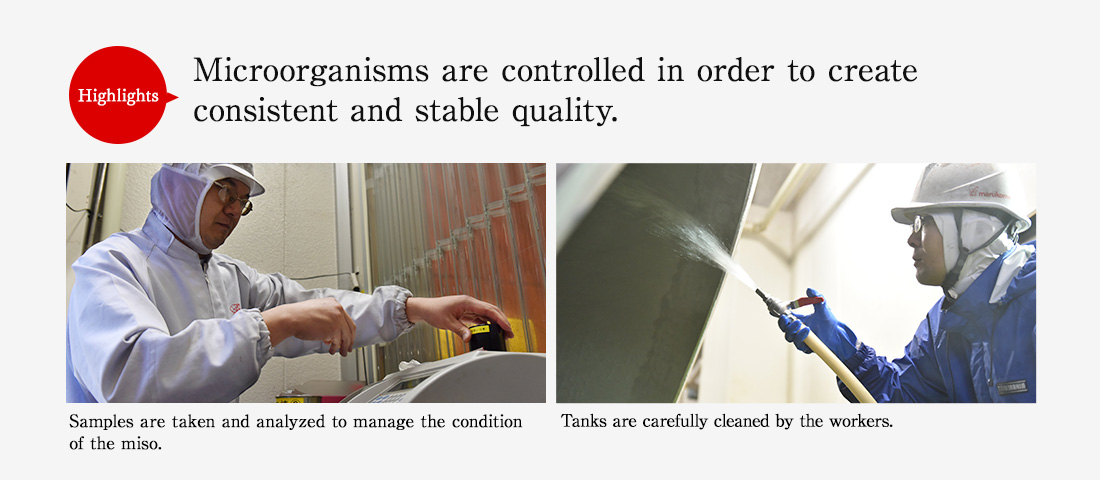

Do we just sit around, waiting for the miso in the tank to finish aging? No. Samples are taken periodically so the Quality Control Section can analyze the data. The progress of fermentation and aging is checked, and the data is used to control the temperature, etc.

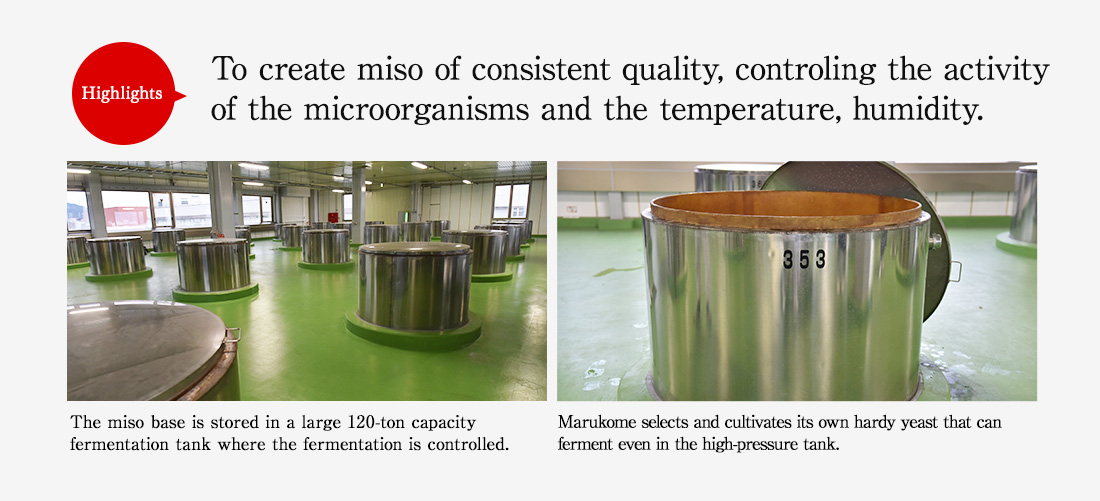

One of the main activities of the Fermentation and Aging Department is the Turning Process where the position of the miso is changed. After fermenting in the large fermentation tank for several weeks, a machine exclusively used to transfer the fermenting miso from the bottom of the tank into another tank. Miso is turned upside down during this process.

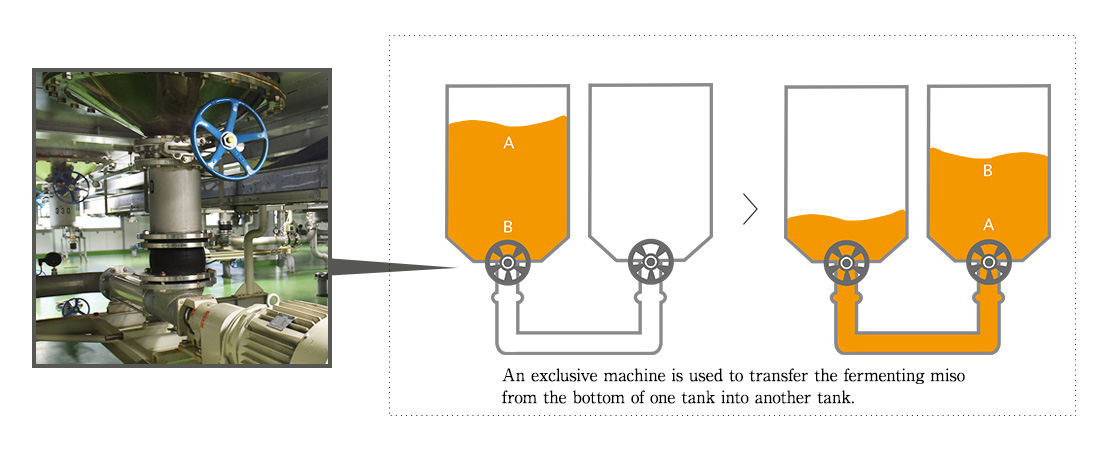

"This is our only chance to visually check the state of all the miso that is fermenting. The Aging Control leader checks the color and aroma." (Nishida)

This is a big job since up to 120 tons of miso are transferred. It is our only chance to add water or koji. This Turning Process is performed twice during the Fermentation Process when we make miso (additive-free miso) in a smaller tank. We use a different turning method in this case.

After the miso is turned, it is allowed to ferment and age in the tank. Samples are taken and analyzed in order to manage the process.

"I take care of several thousands of tons of miso every day. The degree of aging differs for each several hundreds of tanks. If you only look at the numbers, it seems like a big job! As a manufacturer, we cannot condone inconsistent quality. Each step requires attention, but I feel a mission in my work." (Nishida)

The Aging Control leader's job is to manufacture the kuradashi miso, which is the base for each miso product. The aging controller checks the finished kuradashi miso that has been carefully cultured for several months before it is finished. Then, it is sent to the next department where the miso is finished into the final product.

Each department implements very precise measures to prevent contamination. Miso that passes these processes is finished into kuradashi miso. It is essential that we eliminate inconsistency in quality, but this is not easy when working with living microorganisms. We take full advantage of our years of expertise in quality control.

We rely on our equipment in basic areas of quality control. Consequently, the condition of the miso I actually see with my own eyes during the Turning Process is very important. I try to train our workers so that they can interpret the color, aroma, softness, and flavor with their own senses.

I think there are many things we must study and learn in order to consistently create products that satisfy the taste of our customers. I believe that even if it is a labor-consuming process, if it contributes to making our miso more delicious, our motivation will naturally increase, and it will make our customers happy.