When the fresh green onions are delivered to the production line, the roots are removed, and the stalks are arranged on the production line. About ten inspectors check for contamination during this preparation stage.

Mud, grass, small rocks, etc. are washed off using a high-pressure washer, after which the green onions are repeatedly washed with a running water washer and a shower washer. Inspectors bundle the green onions and visually check for foreign matter and green onions of poor color or shape on the production line between each washer.

The cleaned green onions are cut into 5mm lengths, sterilized in chlorinated water, and then washed in a shower. The processed green onions are sent to the next process in a clean state.

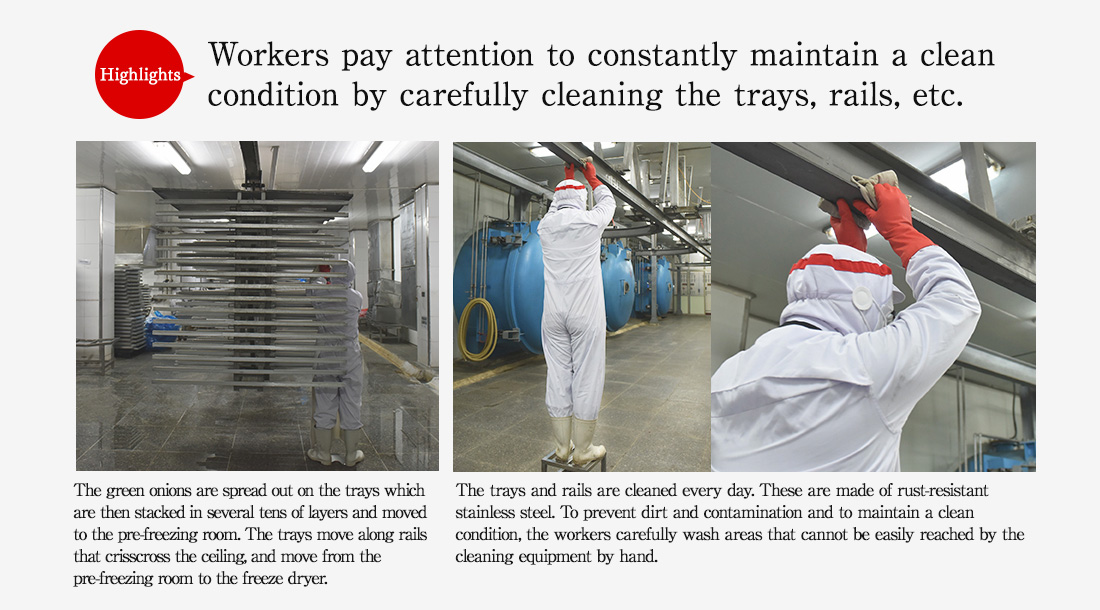

After repeated sorting and washing, the green onions are stacked on an exclusive tray, and sent to the pre-freezing process before being placed in the freeze dryer.

Pre-freezing the green onions improves the water absorption rate after freeze-drying, and improves the finished taste, aroma, color, etc.

The pre-frozen green onions are then placed in the freeze dryer. After vacuum state is achieved, pressure is reduced to sublimate water content and create a high-quality product.

Technology is used to control the balance of freezing, drying, heating, etc. to preserve the flavor of the food.

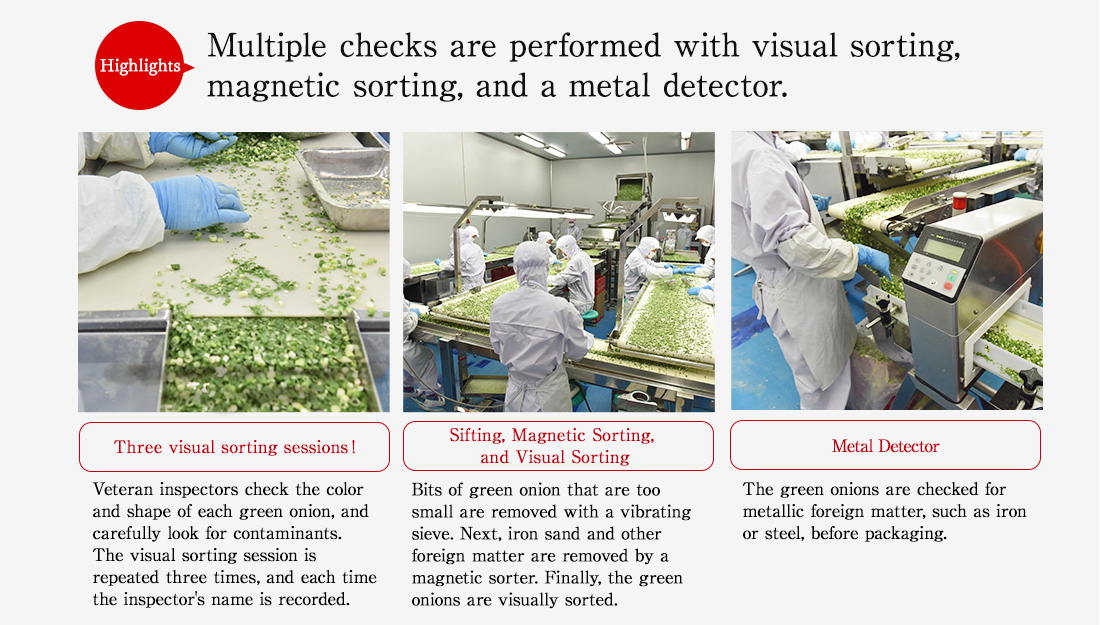

First, the freeze-dried green onions are visually sorted. The inspectors place a handful of green onions on the inspection table and check them.

They look for small bugs attached to the pieces of green onion, or small clear and transparent pieces of vinyl or textile material. The workers patiently carry out this mind-boggling job.

For leafy vegetables that insects especially tend to like, the inspectors pay special attention carefully inspecting and then sorting them.

The inspectors check for contaminants as well as the color and shape of the green onions. Foreign matter and defective pieces are placed on a different tray. This step is repeated three times.

The green onions are sifted with a sieve to remove small items, and then pass through a magnetic sensor and another visual sorting session.Green onions which successfully undergo the strict inspection pass through a metal detector and are then packaged.

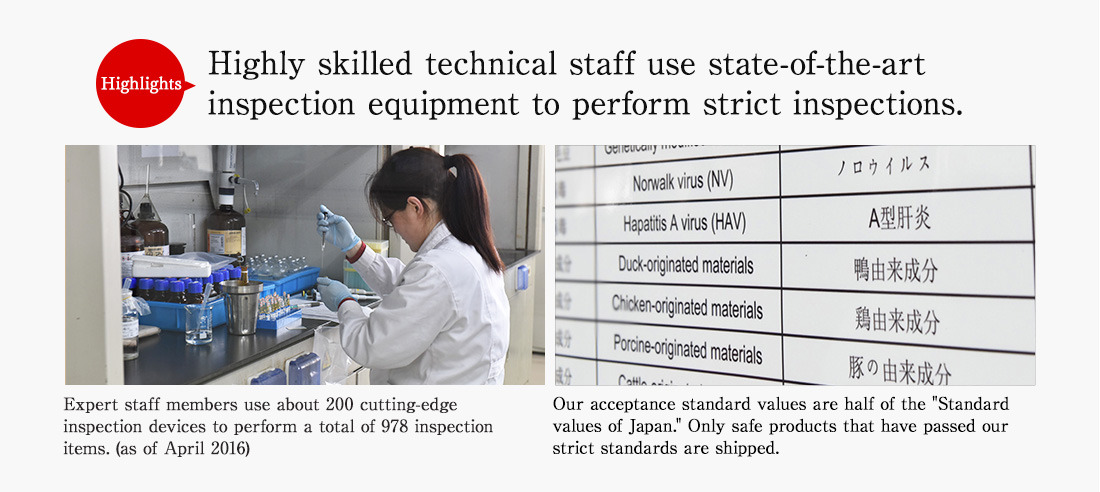

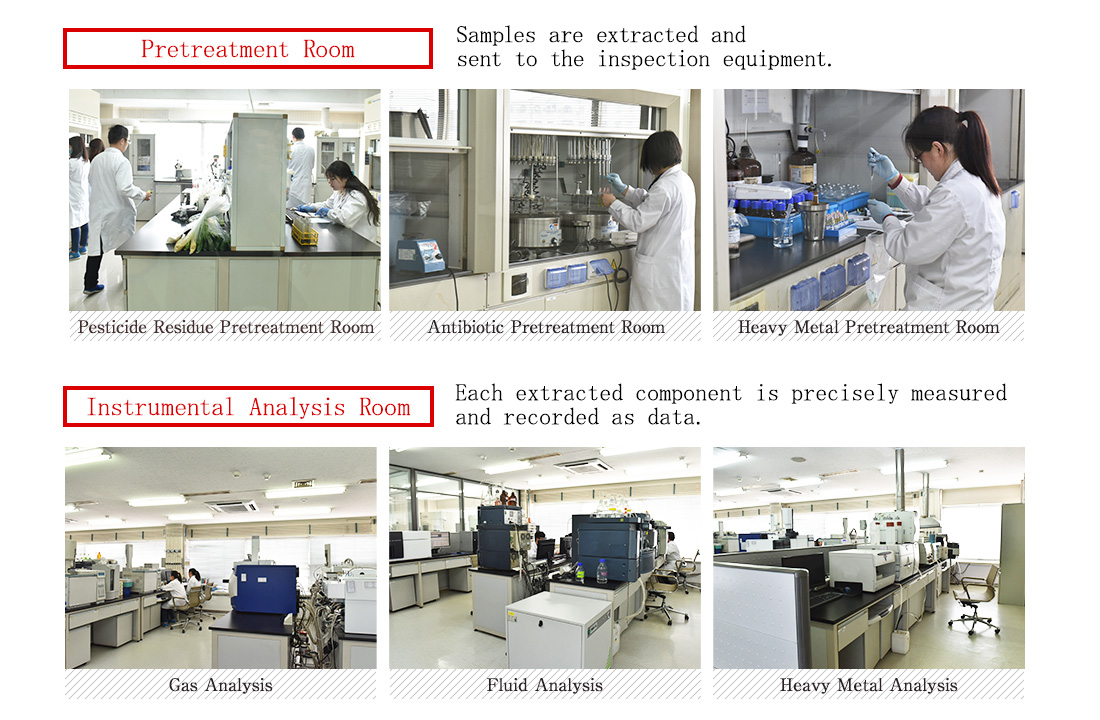

At our Analysis Center equipped with cutting-edge inspection devices, we perform extensive inspections to ensure the safety of our foods.

For example, for pesticide residue, 627 items are inspected, for antibiotics 166 items, and for food additives such as preservatives, sweeteners, and oxidation inhibitors, 65 items. Inspections are also performed for microorganisms, heavy metals, etc., bringing the total number of inspections to 928 items. (as of April 2016)

A sample inspection is taken just before the green onions are harvested. Only those passing the inspection are harvested and sent to the freeze-drying factory. The freeze-dried green onions are inspected again, and only those passing this inspection are shipped.

We also inspect the factory.

We do not compromise in our quality control, and ensure that we provide safe and trustworthy quality to our customers.

The vegetables and marine products used as ingredients are inevitably delivered with small contaminants, insects, and microorganisms. Hence, it's important for us to repeat extensive inspections even though it may seem a bit excessive.

I regularly visit the factory and make sure the work is carried out in the proper environment. I listen to the observations from the factory floor, and personally check the conditions with my own eyes.