將新鮮大蔥送至生產線時,將根去除,並將莖桿排列在生產線上。在準備階段,大約有十名檢查員檢查污染物。

用高壓清洗機洗淨泥,草,小石頭等,然後用自來水清洗機和淋浴清洗機反復清洗大蔥。檢查人員將大蔥捆紮在一起,並在每個清洗機之間的生產線上目視檢查異物和顏色或形狀不良的大蔥。

將清洗過的蔥切成5毫米長,用氯水消毒,然後在淋浴中清洗。經過處理的大蔥以乾淨的狀態發送到下一個過程。

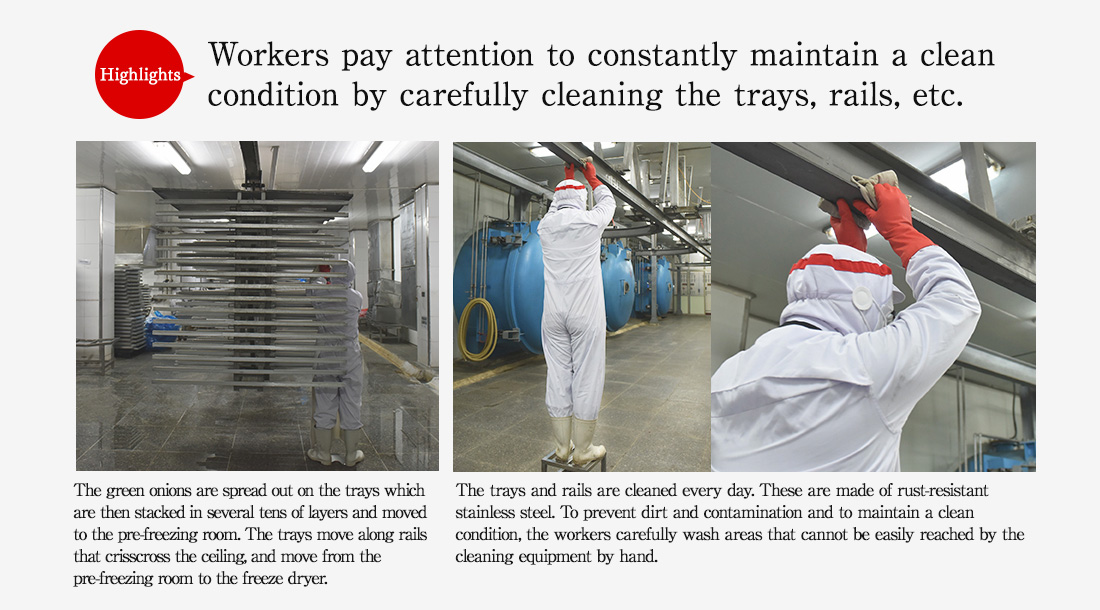

經過反複分揀和洗滌後,將蔥堆疊在專用托盤上,並送入預冷凍過程,然後放入冷凍乾燥機中。

預冷凍大蔥可提高冷凍乾燥後的吸水率,並改善最終的口感,香氣,顏色等。

然後將預冷凍的蔥放入冷凍乾燥機中。達到真空狀態後,降低壓力以昇華水含量並生產出高質量的產品。

技術用於控製冷凍,乾燥,加熱等的平衡,以保持食物的風味。

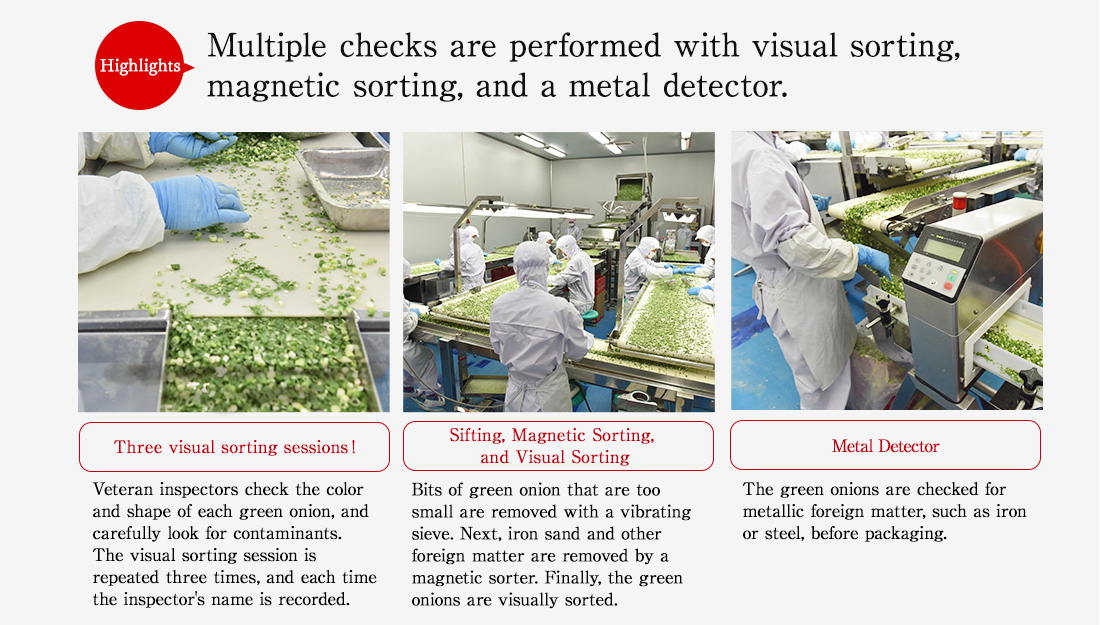

首先,對冷凍乾燥的大蔥進行目視分類。檢查人員在檢查台上放了幾把蔥,然後檢查了一下。

他們尋找附著在蔥片上的小蟲子,或乙烯基或紡織材料的透明小碎片。工人耐心地完成這項令人難以置信的工作。

對於昆蟲尤其喜歡的多葉蔬菜,檢查人員應特別注意仔細檢查並分類。

檢查員檢查污染物以及蔥的顏色和形狀。異物和有缺陷的碎片放在另一個托盤上。重複此步驟3次。

將大蔥用篩子過篩以除去小物品,然後通過磁傳感器和另一個目視分類。成功通過嚴格檢查的大蔥通過金屬探測器,然後包裝。

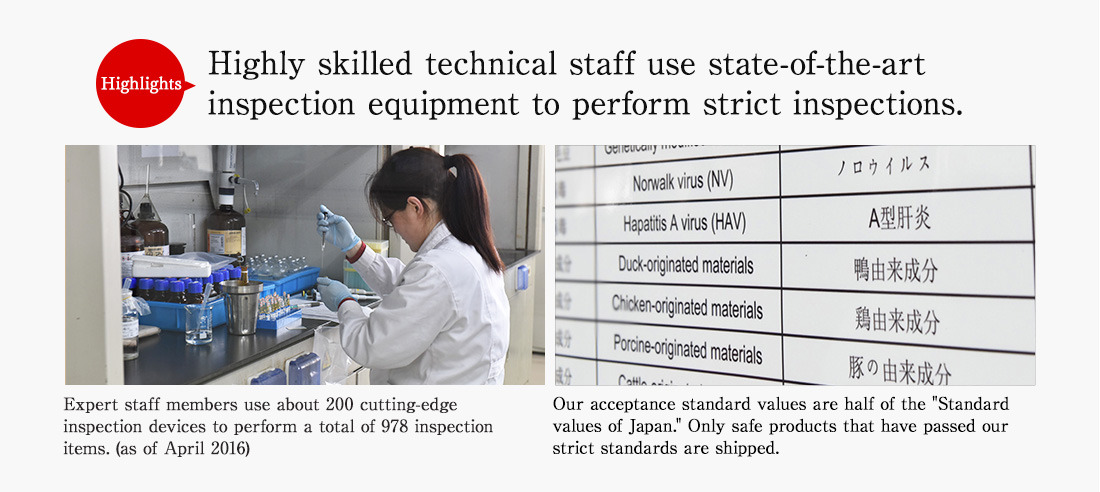

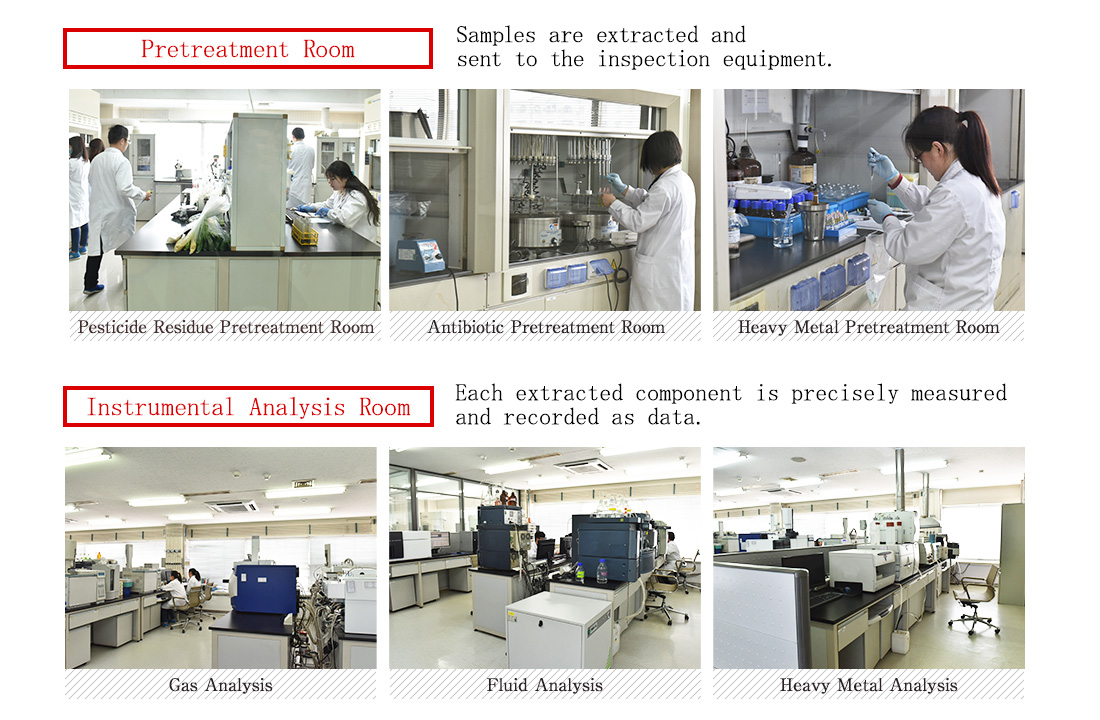

在配備了先進檢驗設備的分析中心,我們進行了廣泛的檢驗,以確保我們食品的安全。

例如,對農藥殘留進行了627項檢查,對抗生素進行了166項檢查,對食品添加劑(例如防腐劑,甜味劑和抗氧化劑)進行了65項檢查。還對微生物,重金屬等進行檢查,使檢查總數達到928件。 (截至2016年4月)

在收穫大蔥之前進行抽樣檢查。只有通過檢查的人員才能收穫,然後送到冷凍乾燥工廠。再次檢查冷凍乾燥的大蔥,並且僅運送通過此檢查的蔥。

我們還檢查工廠。

我們在質量控制方面不妥協,並確保我們為客戶提供安全和可信賴的質量。

用作成分的蔬菜和水產品不可避免地會帶有少量污染物,昆蟲和微生物。因此,對我們來說重複重要的檢查很重要,即使這可能看起來有些多餘。

我定期拜訪工廠,並確保工作在適當的環境中進行。我聽從工廠車間的觀察,並親自檢查情況。