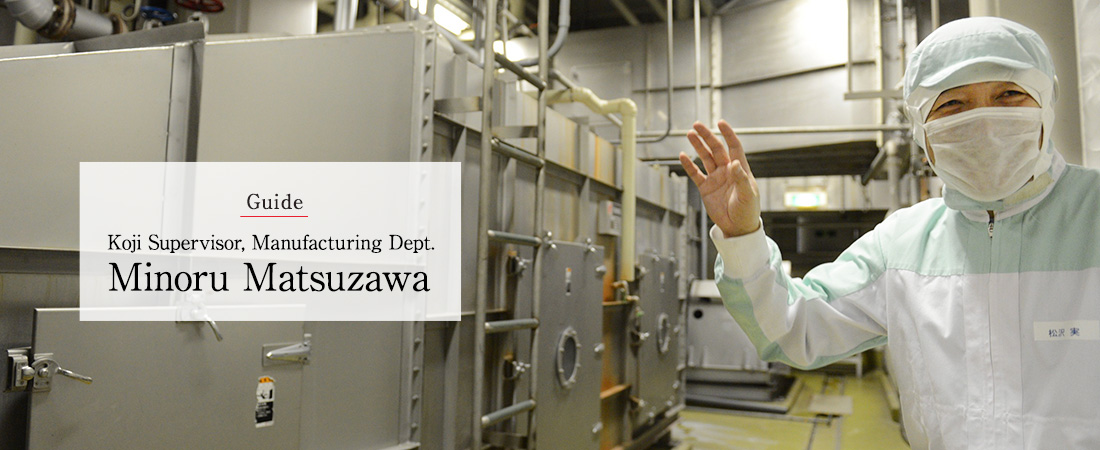

Rice that has been milled and sorted at the rice milling plant is delivered to the factory, where it undergoes strict checks.

Each delivered lot is inspected for discolored rice, miscellaneous grains, and foreign matter.

放射性检查:确认大米的安全性。

磁铁:去除金属片等。

风力分级机:灰尘和少量异物被吹走。

金属探测器:此处去除了铜和铝等有色金属。

擦米机:去除米糠和粘附在米表面的细小杂质。

磁铁:再次使用磁铁去除残留的金属碎片等。

颜色分选机:高精度传感器可立即判断与大米颜色不同的异物,例如变色的大米和石头。

每天最多运送120吨大米(价值6辆大卡车)。每粒大米都经过检查。

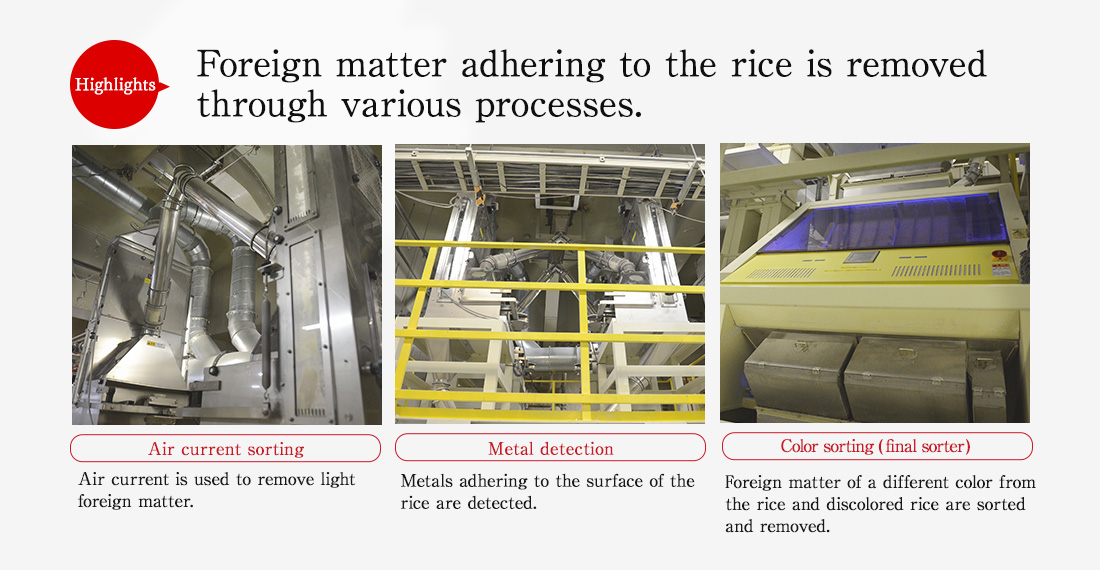

成功通过分选过程的大米放在一个13吨的巨大水箱中,并浸泡在水中。大米吸收水的速度根据大米的类型和外界温度而变化,因此每批产品都是单独调整和控制的。浸泡数小时后吸收水分的大米被排干,然后送至蒸煮过程。这是制米麴和味噌制作过程中的重点。

理想情况下,蒸米饭应具有坚硬的外观和柔软的内部。在这种状态下,创建了一种米麴菌可以生长细菌丝的环境。在另一方面,如果米饭有硬核,它可以导致成品粗糙或迟钝味噌。中央控制室中的电子操作与工厂车间工人的手动操作相结合,可以制成高度完美的米饭。

将蒸好的米饭冷却至合适的温度以生长出米麴菌,便经历了称为“播撒米麴菌的过程,将米麴菌引入大米中。然后将混合物迅速分散到整个制米麴设备中。它的直径为16米,容量为35吨,看上去就像是科幻电影中的东西。大米在这里停留约40个小时,然后转化为米麴,其中含有约20.0千克的大米。 30种不同的酵素。

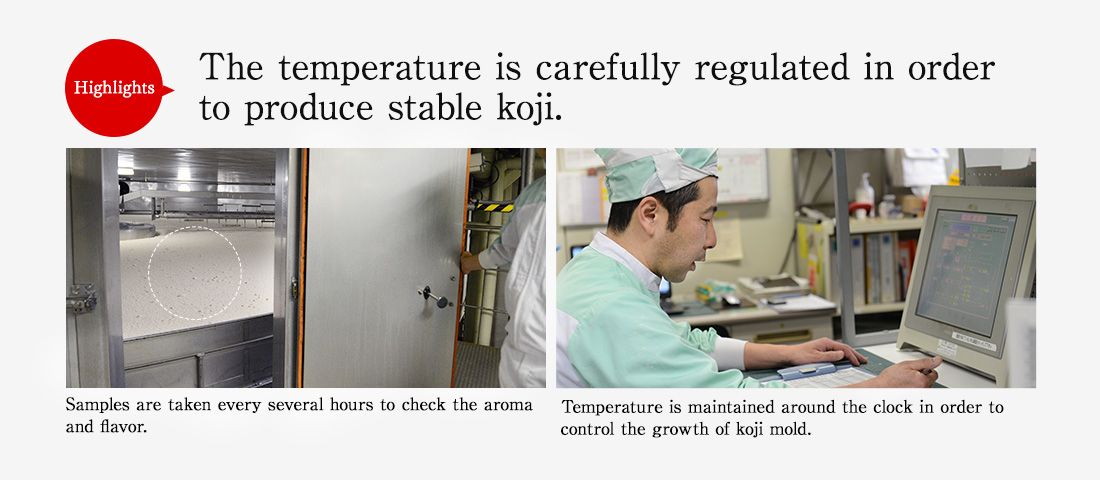

这个过程也是在电子和手动操作的共同努力下进行的。工人每隔几个小时取样一次,以检查香气和风味,因此中央控制室会不断检查米麴的状况。工人拥有多年的经验,可以用来维持稳定的质量。

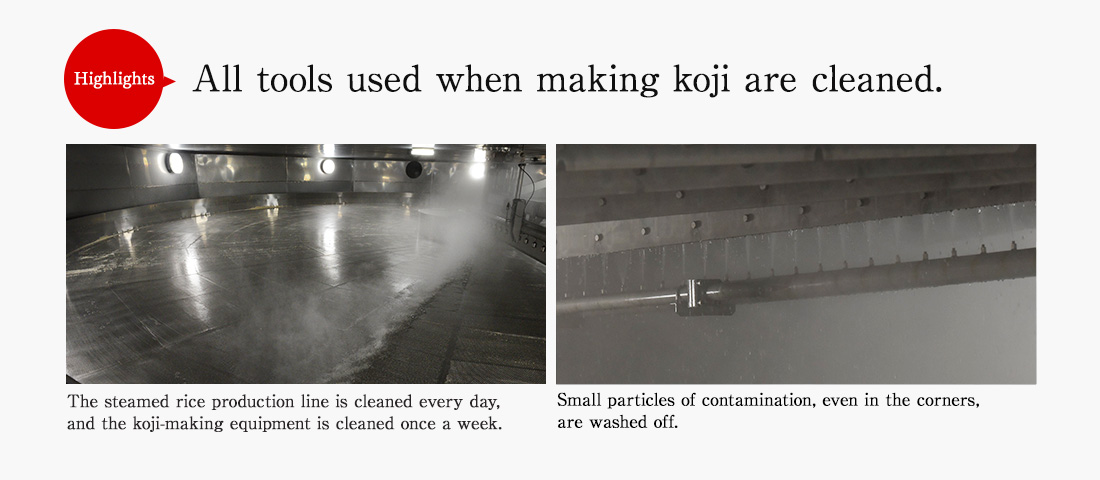

我们不遗余力地保持清洁的工厂环境。每周一次,我们停止所有准备工作,并花时间进行清洁。

“我们每天清洗蒸米生产线。我们生产的产品供客户消费,因此清洁是我们不可忽视的重要工作。” (松泽)

米麴所需的工具,包括皮带输送线,制造相关设备以及用于运输的储罐,均已清洗并重置。一天结束时看到闪亮的设备感觉很好。

诚实地工作很重要。我们不能偷工减料,也不能跳过一步。我认为,如果诚实地开展工作,结果自然会随之而来。重要的是,不仅要考虑作为制造商,还要考虑作为客户。

仅从制造商的角度来看,例如“这是我们努力做到的努力”,是不够的。在这种情况下,永无止境的挑战是制造出无误的产品。在培训工人的工作时,我们使用手册。这就是为什么我总是尝试对“我们为什么进行这项工作”进行解释。重要的是要记住,我们正在创造客户的需求。我认为了解这种原因会激励我们开展更好的工作。