将新鲜大葱送至生产线时,将根去除,并将茎杆排列在生产线上。在准备阶段,大约有十名检查员检查污染物。

使用高压清洗机洗净泥,草,小石头等,然后用自来水清洗机和淋浴清洗机反复清洗大葱。检查人员将大葱捆扎在一起,并在每个清洗机之间的生产线上目视检查异物和颜色或形状不良的大葱。

将清洗过的葱切成5毫米长,用氯水消毒,然后在淋浴中清洗。经过处理的葱以干净的状态发送到下一个过程。

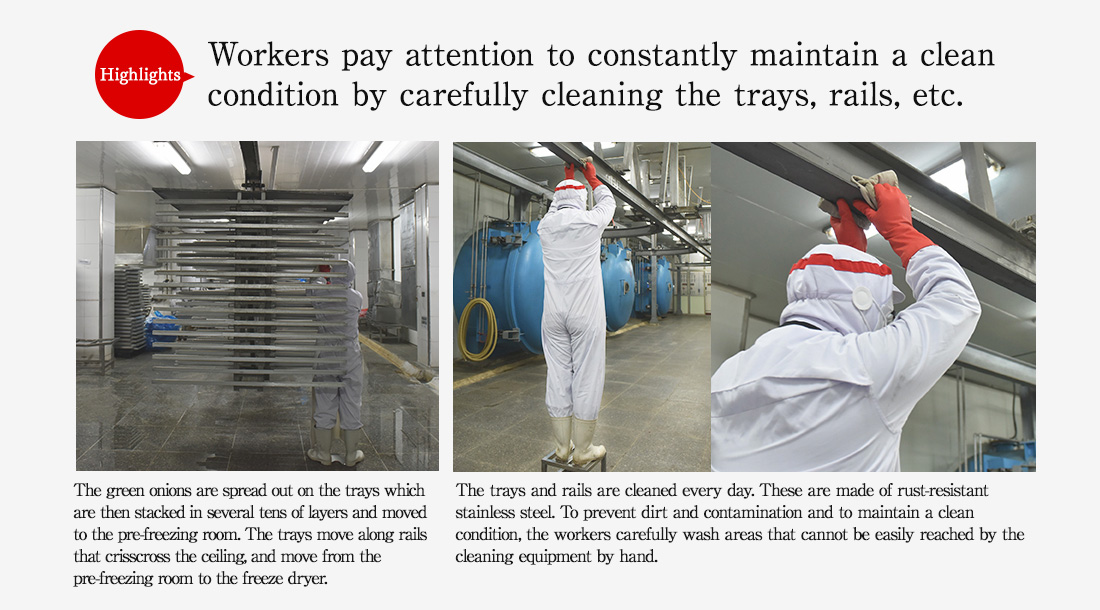

经过反复分拣和洗涤后,将葱堆叠在专用托盘上,并送入预冷冻过程,然后放入冷冻干燥机中。

预冷冻大葱可提高冷冻干燥后的吸水率,并改善最终的口感,香气,颜色等。

然后将预冷冻的葱放入冷冻干燥机中。达到真空状态后,降低压力以升华水含量并生产出高质量的产品。

技术用于控制冷冻,干燥,加热等的平衡,以保持食物的风味。

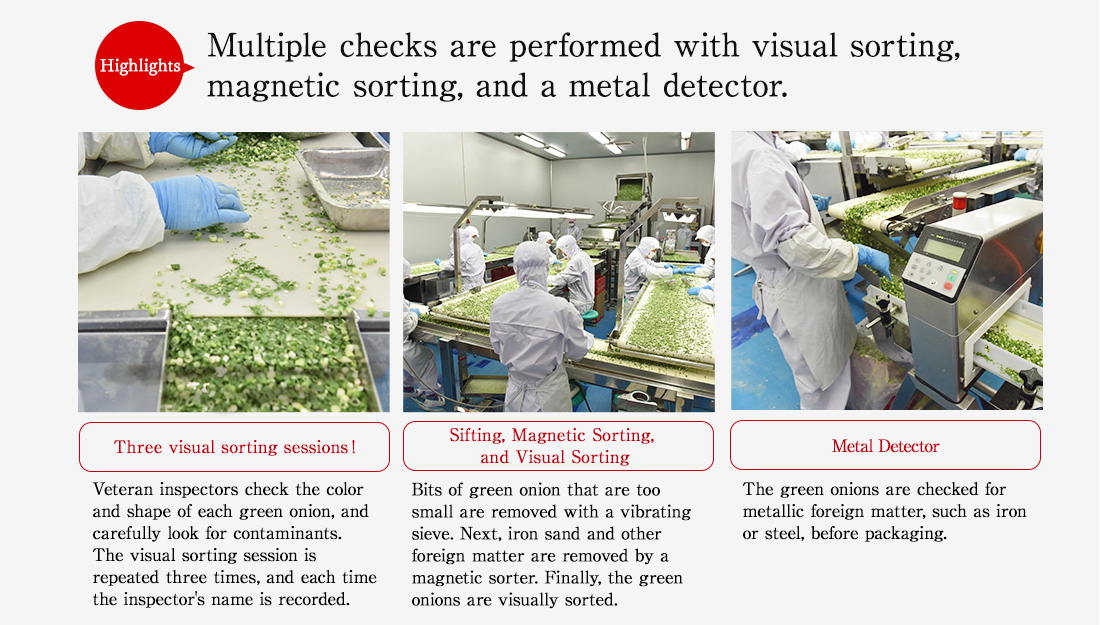

首先,对冷冻干燥的大葱进行目视分类。检查人员在检查台上放了几把葱,然后检查了一下。

他们寻找附着在葱片上的小虫子,或乙烯基或纺织材料的透明小碎片。工人耐心地完成这项令人难以置信的工作。

对于昆虫尤其喜欢的多叶蔬菜,检查人员应特别注意仔细检查并分类。

检查员检查污染物以及葱的颜色和形状。异物和有缺陷的碎片放在另一个托盘上。重复此步骤3次。

将大葱用筛子过筛以除去小物品,然后通过磁传感器和另一个目视分类。成功通过严格检查的大葱通过金属检测器然后包装。

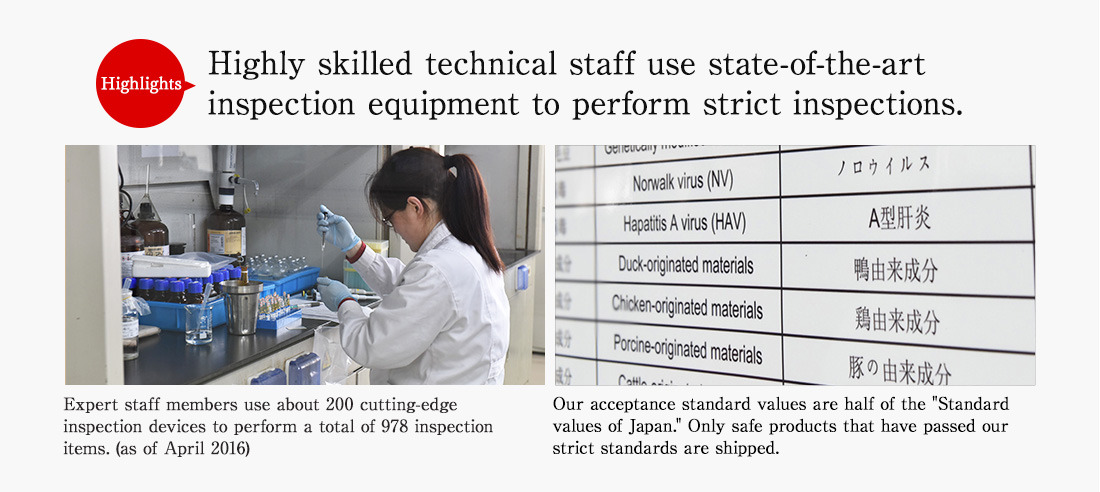

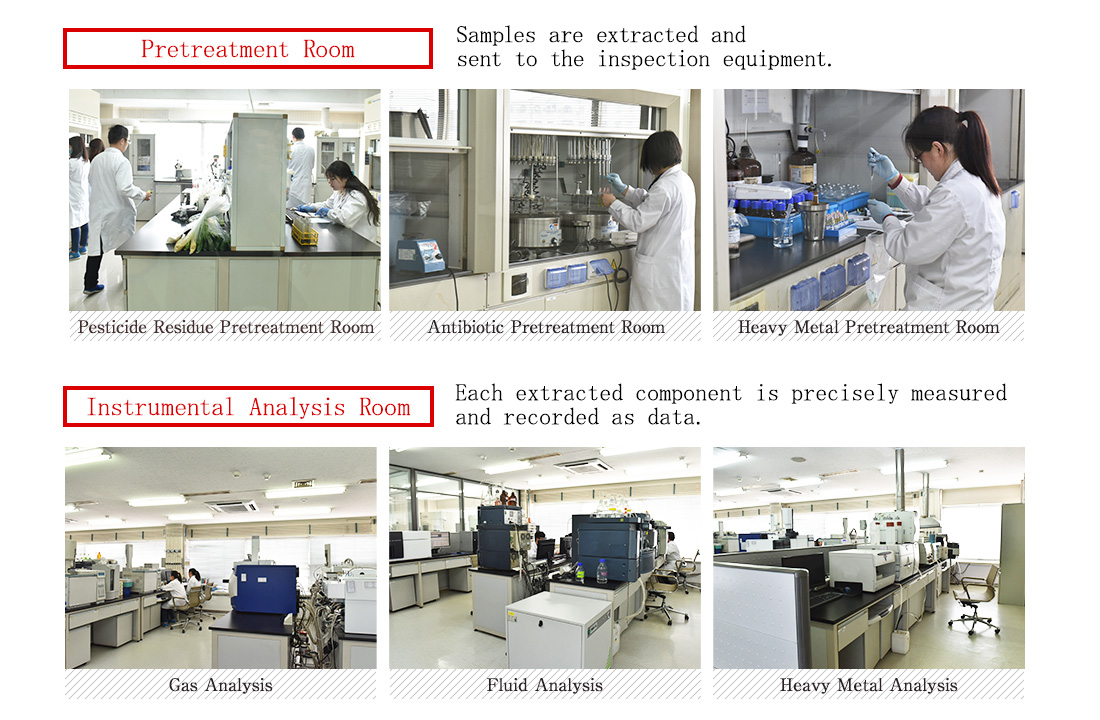

在配备了先进检验设备的分析中心,我们进行了广泛的检验,以确保我们食品的安全。

例如,对农药残留进行了627项检查,对抗生素进行了166项检查,对食品添加剂(例如防腐剂,甜味剂和抗氧化剂)进行了65项检查。还对微生物,重金属等进行检查,使检查总数达到928件。 (截至2016年4月)

在收获大葱之前进行抽样检查。只有通过检查的人才能收获,然后送到冷冻干燥工厂。再次检查冷冻干燥的大葱,并且仅运送通过此检查的葱。

我们还检查工厂。

我们在质量控制方面不妥协,并确保我们为客户提供安全和可信赖的质量。

用作成分的蔬菜和水产品不可避免地会带有少量污染物,昆虫和微生物。因此,对我们来说重复重要的检查很重要,即使这可能看起来有些多余。

我定期拜访工厂,并确保工作在适当的环境中进行。我听从工厂现场的观察,并亲自检查情况。