冬季和春季,新鲜收获的裙带菜被运送到我们的沿海种植农场。在某些日子里,交付了100吨。

裙带菜立即被送到洗涤和分选过程。然后将其以新鲜干净的状态腌制。

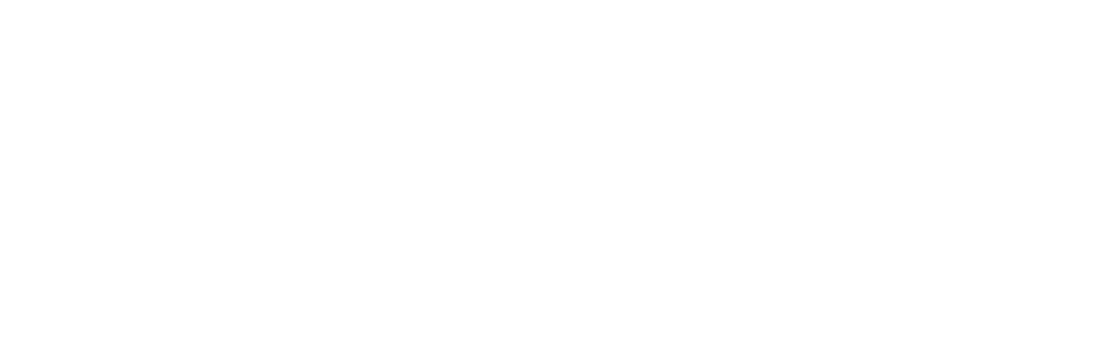

将腌制的裙带菜静置一会儿,然后仔细分类。工人在包装时检查异物。

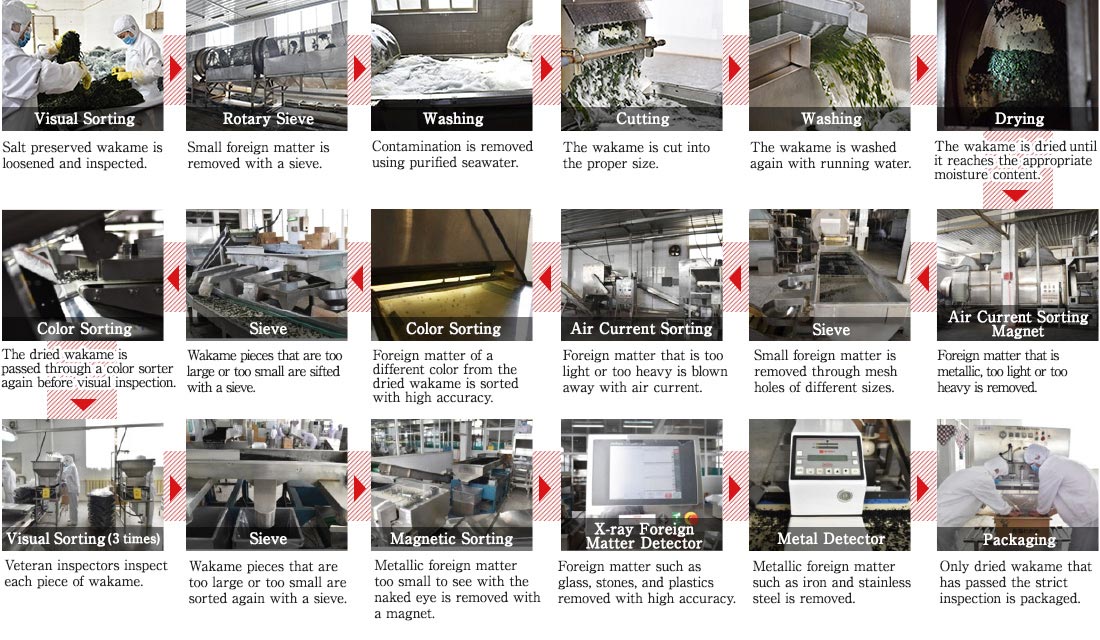

首先目视检查运送到工厂的腌裙带菜工人将裙带菜放在生产线上时用手将其松开。

为了确保我们提供给客户的产品的安全性和可信赖性,只有从交货阶段开始就经过严格检查的产品才可以进入下一个流程。

我们的工人认真认真地执行每一步,并不断寻求更高的质量。

我们还参与了环保计划,例如重复利用在动物饲料分选过程中被拒绝的裙带菜

在自然环境中养殖的水产品中可能附着有许多不同种类的异物,无论大小,异物都是如此。

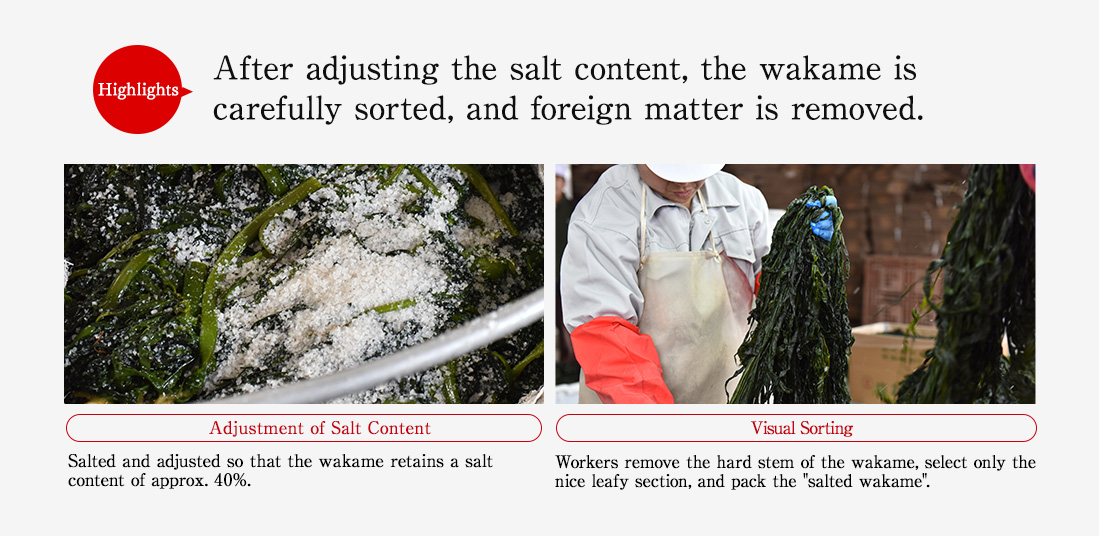

裙带菜在大筛子中旋转了很长时间。在此期间,它松动了,并且去除了诸如沙子,盐,小鱼和虾之类的小杂质。

筛选后,裙带菜用流水彻底清洗。在三到四次清洗过程中,下沉或漂浮的异物将被清除。

将裙带菜干燥直至水分在6%至8%之间。收缩到几毫米的大小后,将其发送到风力分级机工艺中。

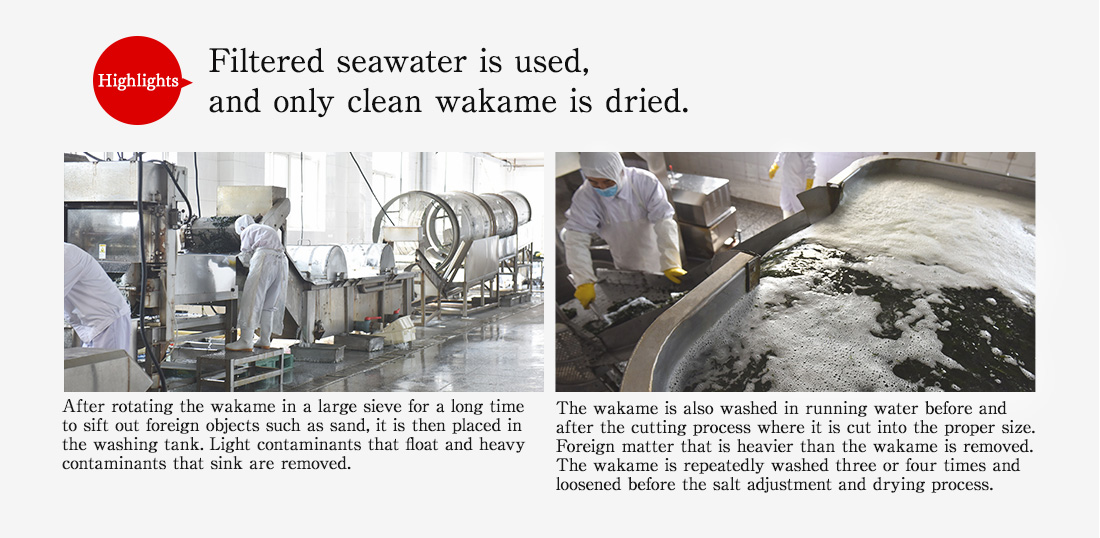

裙带菜用去除重杂质的机器和去除轻杂质的机器仔细分类。

裙带菜经过各种过程,包括用磁铁去除金属物体,以及两个筛孔大小不同的筛子。它第二次通过气流分选器,最后经过颜色分选器,以根据颜色密度的差异除去异物。

我们执行多次检查,以保持更高的质量。我们的目标是执行更严格的检查,并追求安全性。

经验丰富的检查员会检查每片经过约50裙带菜50厘米宽的皮带输送机。我们的检查员每天目测整理约3吨裙带菜

专业检查人员应清除裙带菜,并清除任何细小的异物。

被检查的裙带菜被放入袋中,并送至第二次目视分类。

总共进行了三个视觉分类会议,在此期间检查样品以确认裙带菜质量是可以接受的。

裙带菜用人的手和眼睛分类后,再次通过筛子。

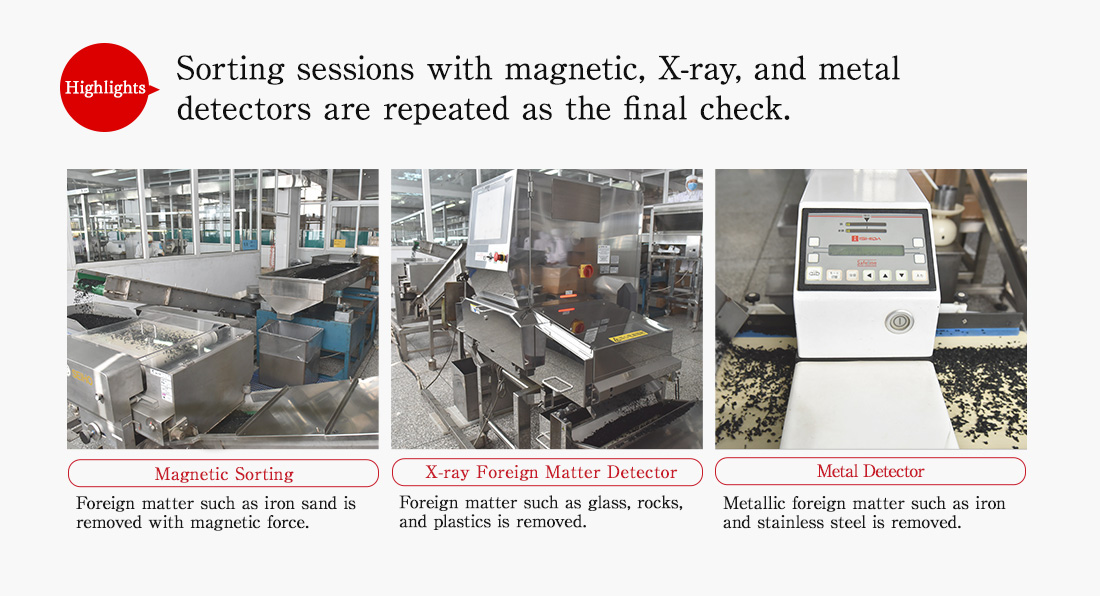

然后通过三步检查,包括磁检测器,X射线异物检测器和金属检测器。经过这些检查,裙带菜最终被送到包装过程。

从各种角度和方法验证并采取了防止异物污染干裙带菜

我们希望我们的客户继续喜欢丸米品牌。我们每天努力不断提供安全可靠的产品。

我们希望我们的客户认识到,即使在我们的量产产品中,也有很多人参与其中。